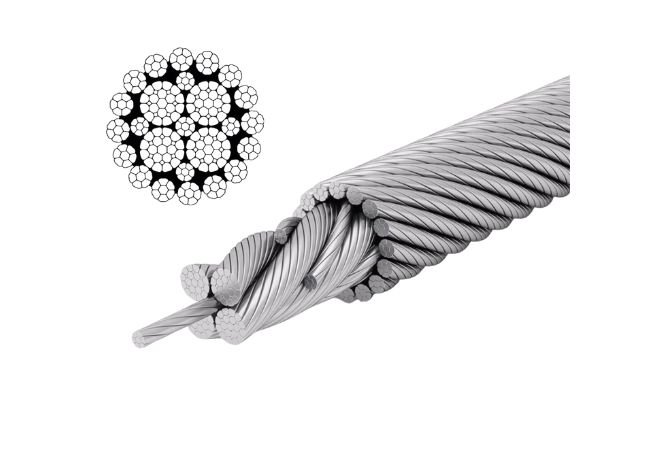

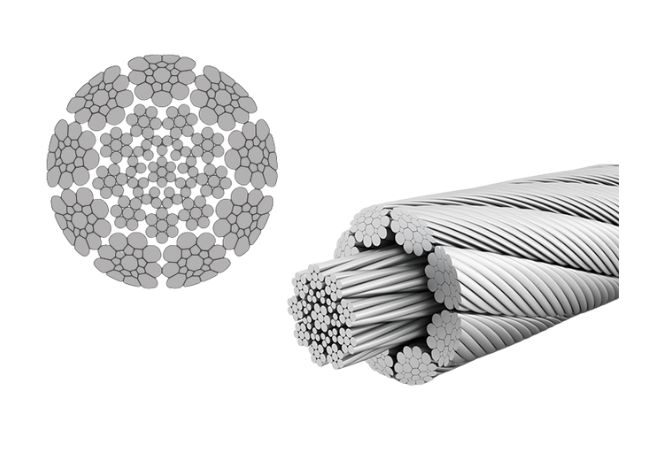

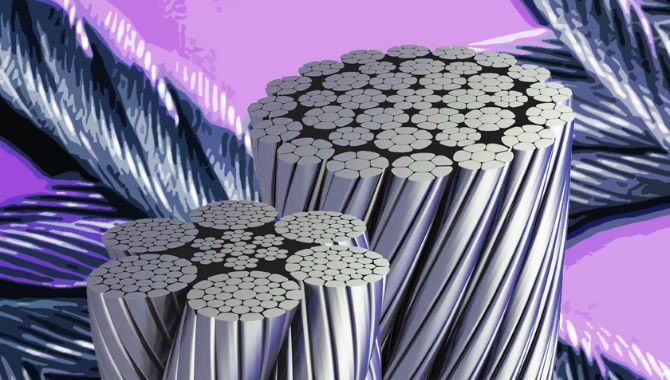

Compacted Wire Rope

The main benefit of stainless Steel cable over other types of cable is its corrosion resistance. This characteristic works well in high moisture and acidic environments, such as in marine rigging applications. GuoFeng Produce an extensive range of compacted wire ropes that are made in two different finish process such as ungalvanized and galvanized. Due to its compact design, this wire rope can offer excellent features such as:

- Wear and water resistance

- Can stand to sock load and high load

- Easy to handle

- Better fatigue life

- Low deformation

GuoFeng – Your Leading Compacted Wire Rope Supplier

The wire rope is commonly made from various wire strands. These is manufactured with the help of crimping wheels that use to shape and compress the wire in order to form compacted structures. In this process, we create a flattened outer surface. Aside from that, it increase the contact area of wire ropes between strands.

We manufactured this type of wire because it can provide high strength and much better crush resistance. Aside from that, it has a low stretch which makes them provide high performance and lifetime service.

GuoFeng can provide a wide range of compacted wire rope that comes in sizes, colors, and materials. You can request customizations depending on your needs especially if you have a business and to enhance your business. We make sure that for every wire rope you purchased, you can get this at a reasonable price.Make you more competitive and win business!

Great Advantages

Our compacted wire rope can offer excellent advantages such as:

- Higher flexibility

- Lower contact pressure

- Its contact area has a larger surface

- Can stand against corrosion, abrasion, vibrations, mechanical damages, and more.

- Higher breaking load

- Offer less maintenance

- Excellent cover to avoid damages and more.

Different Types of Compacted Wire Ropes

Plastic Injected Wire Ropes. These wire rope are made of plastics where in the plastics injected in wire core. It is a type of wire rope that has the ability to reduce friction.

General Wire Rope. It is known as standard type for all types of wire ropes. It is made through the construction of both outer and inner wires.

Fiber Infilled. The outer surface of these wire ropes is added with fiber while the inside for this has a lubricant. It has the ability to maintain the stability of wire ropes, Make the toughness of the steel wire rope stronger.

Different Applications

Compacted wire ropes can be used in different fields of application including::

- Winch cable

- Boom hoist ropes

- Logging mainlines

- Clam shell buckets

- Anchor lines

- Trailer loader

- Trolley lines

- Whip hoist ropes

- Pilar crane ropes

- Deck crane ropes

- Offshore crane ropes

- Mining ropes

- Machinery, Marine fishing, and more.

Certifications

We passed different international certifications in order to provide quality assurance such as:

- CE Certification

- LRS

- LR

- ISO 14001

- ISO 9001

- RoHS and so on.