Industries We Serve

Why Choose GuoFeng Services

GuoFeng has over a decade of experience manufacturing and performing roll-swagging wire ropes.

Skilled engineers support our in-house advanced equipment for all manufacturing procedures.

Our produced components are ISO9001-certified and approved. Also, they are traceable and safe to use.

Our approachable service team is always ready to accommodate your inquiries and provide services.

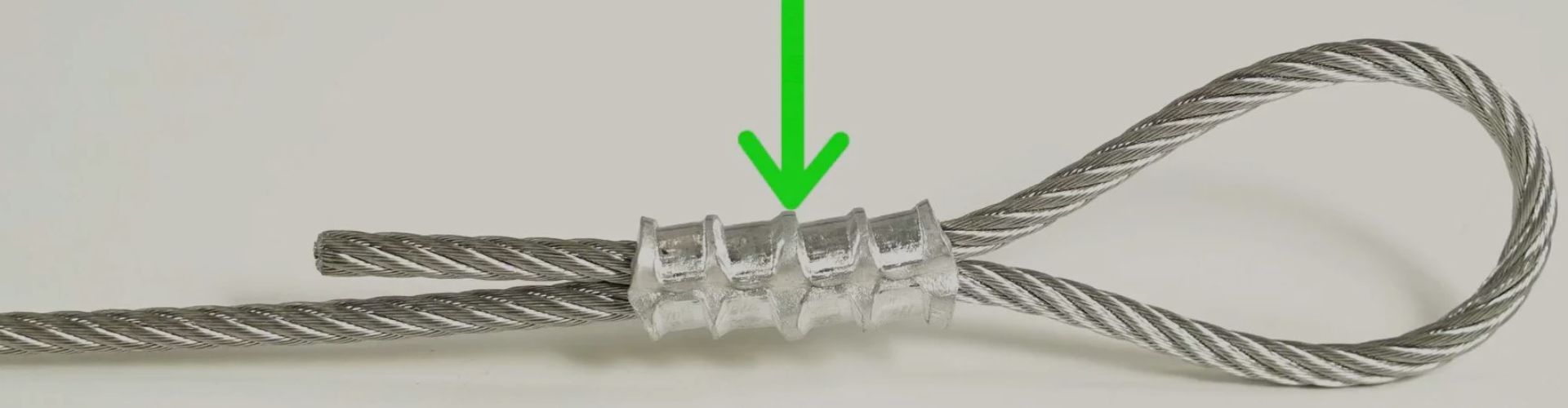

GuoFeng Roller Swagging Process

GuoFeng team operates a simple roller swagging procedure. It is performed using the rotary swagging machine. This process sets the wire ropes and hammers their external diameter. In such a step, the flat and compact rope strands are achieved.

The cables are fed in the middle of the swagging machine’s active part. A couple of hammers are in it, about 180° far from each other. Both swag in and out when the device rotates. As the process is performed repetitively, a smaller diameter is achieved.

Strengths of our Roller Swagging Machine

Our roll swagging service provides the following product benefits.

- Efficient Finishes. It gives an efficient finish which eliminates further necessary operations.

- Flexible Tooling. These machines offer versatile, quick, user-friendly tooling and are practically ideal.

- Finest Control. A range of diameters allows for the most precise wall thickness control.

- Minimized Material. It only uses precise sizes and finishes, so there’s no waste of materials.

- Systematic Approach. All necessary tasks are completed systematically via machines.

- Speeds Assembling. Attaching components is possible relatively with wire cable, hose, etc.

Importance of Swaged Wire Rope

Three factored details determine the importance of wire rope, precisely a rolled swaged process type. Here are the following.

- When the wire rope has a smooth surface, pulleys can easily slide on it. Moreover, the force needed is minimal as it has better movement on sleeves.

- The rope has to be stiffer, depending on applications. It enables buckling, especially when under pressure.

- A wire rope that undergoes swaging process has an enhanced capacity. It improves fraying resistance for the cables to get cut.