Zip lines are mainly a recreational tool that typically consists of a wire rope installed on a slope with the main body of the rope remaining suspended over a steep fall.

Usually, the wire ropes are fitted with a pulley that provides additional support to people as they slide across. The wire rope should therefore be of the best quality and strong to be able to support people of different weights without breaking.

Features of the Best Wire Rope for Zip Lines

Here are some important features you must consider:

1.Material

The material of the wire rope is one of the most important factors to consider. The material will determine how strong and durable your wire rope will be.

When selecting the materials you should also take into consideration factors such as their resistance to corrosion, rust, and wear as well as their weatherproofing features such as UV resistance and being waterproof.

The best material recommended for this application is galvanized steel not only is it stronger but it is rust-proof as well.

For instance, you can choose steel wire rope , stainless steel wire rope , galvanized wire rope , or any other material.

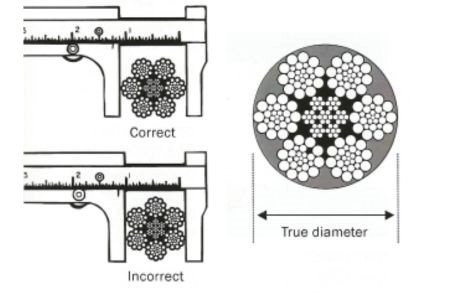

2.Diameter

When it comes to wire ropes their diameter is typically equated to their overall strength. The thicker the wire rope the stronger the rope will be.

When selecting the best diameter for your zip line it is also best to consider your installation requirements.

If the line needs to be tightened then the wire rope should have a thicker diameter. If you intend to leave more room by having the zip line sag down then a thinner diameter will be the better.

3. Breaking Strength

In simpler terms breaking strength is a measure of how much pressure or weight can be tolerated by the wire rope before it reaches its breaking point.

With zip lines, it is best to select a wire rope with a high breaking strength. The zip lines need to be strong as well as durable in order not to pose a safety hazard. Therefore, the higher its breaking strength the more durable and secure it will be.

4.Cable Swage

This is a secured loop that functions as an attachment point for the wire rope and other components such as the pulley. It is designed using a sturdy cable which is then pressed to create a secured loop.

There are different varieties of cable swage, there is the raw cable that will require looping to properly function. The other design is the swaged loop that comes ready to use with a loop on one end or some designs incorporate a loop on both ends.

5. Length

The length of the wire rope is another important factor to consider. The perfect length for your zip line much like its diameter depends on how you intend to install your wire rope.

If the wire rope is going to span for close to a mile then it should also be thicker to support additional weight. Shorter ropes can be thinner in diameter.

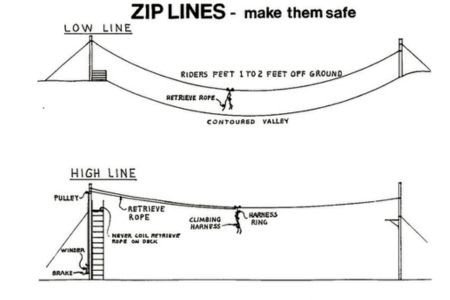

6.Installation Method

You should install the zip line in the most secure way possible. Several methods can be used to install the line the best one being bolting the wire rope for a more permanent attachment especially when using poles

Other tips to consider when installing the wire rope include;

- Preparing the ends of the wire rope

- Setting up both the starting and ending anchors

- Connecting the wire rope to the trolley

- Securing the cable using tension

Conclusion

Aside from the mentioned features it is important to ensure that the wire rope you select has passed all the set standards. These standards include those set by TSSA, ACCT, and CSA. You should also pass any locally set regulations. This is vital as safety is paramount when it comes to zip lines.

More Resources :

Wire Rope Assembly – Source: IQS Directory

Zip Line – Source: WIKIPEDIA