Making plans to buy the best lifting sling must be done with care.

Due to the many types of these slings, there are, you should know the different features that will help in deciding what will work out for the specific lifting job.

Chain slings, wire rope slings, and synthetic web slings can all be used. But, when should you choose a specific sling for your applications:

What is Wire Rope Sling?

Wire rope slings represent a valuable piece of the rigging hardware family. You can use them in different industries to meet different lifting and hoisting needs. The sling links loads to lifting devices and is available in different configurations for various uses.

What is Chain Sling?

Chain slings represent the lifting devices made of alloy steel. They are made of chains and come with a hook, links, and some other unique fittings. All these come together to help in its ability to load and lift equipment.

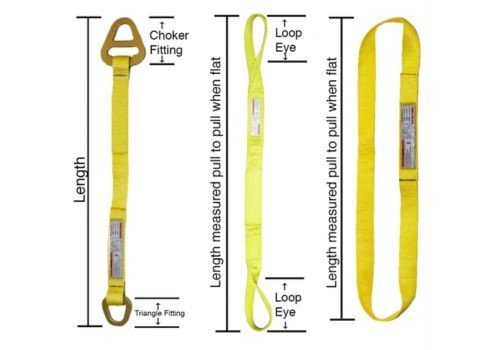

What is a Synthetic Web Sling?

Synthetic web slings stand as a great choice when there is a need for delicate equipment or highly finished parts to be kept safe from damage.

Due to its ability to grip tightly through molding and conforming to surfaces, you can use these accessories in many industries.

Differences in these Types of Slings

Below are the major differences between these slings;

| Comparison List | Synthetic Web Slings | Wire Rope Slings | Chain Slings |

| Materials | Made from synthetic materials of high strength such as polyester, nylon, or polypropylene. | Made from steel cables of high strength, they are made mostly from alloy steel. | Composed from metallic chain links mostly alloy steel.

|

| Strength | Come in different weights based on the material, width, and construction. They are also perfect for different load sizes. | They have high weight-bearing capabilities and are used mostly for lifting heavy-duty tasks. | Come with very high weight-bearing capacities. This makes them ideal where oversized and heavy loads are concerned. |

| Variety | These slings come in different configurations. These include round slings, flat webbing slings, and more. Its configurations differ from. the other slings in comparison. | The different types of these slings include multi-leg, single-leg, as well as braided configurations which differ from that of synthetic web slings. Each of these configurations meets different lifting needs. | These slings come in a variety of configurations such as adjustable leg, single leg, and double leg designs. All these designs offer flexibility where lifting is concerned. Although similar to wire rope slings, they are still different from other slings where variety is concerned. |

| Flexible nature | Are lightweight and flexible. This makes handling them easy. It also makes them versatile for different lifting uses or applications. | Although not as flexible as synthetic web slings, these slings are adaptable. They can also handle rough surfaces and sharp edges perfectly. | Compared to synthetic web and wire rope slings, chain slings are the least flexible. However, they are adjustable through unique attachment points. This makes it easy for them to adapt to various load sizes and shapes. |

| Safety | Comes with color codes that show their capacity and help in their safe use. | Unlike synthetic web slings, wire rope slings require regular inspections to check wear and damage for safety when used. | Compared to synthetic web and wire rope slings, chain slings mostly have the highest level of visibility. This is because of their metallic makeup which enhances safety when used for lifting applications. |

| Durability | Compared to the other slings, they have low abrasion and cut resistance. Also, their low heat resistant feature means they shouldn’t be used in applications where there is high heat. This also makes them different from wire rope and chain slings. | Can resist abrasion and withstand high-temperature levels. This makes them perfect for harsh environments. However, they can corrode with ease from within. | Are highly resistant to abrasion, wear, and damage. This makes them ideal for environments that are demanding. |

| Applications | Used in industrial rigging, Shipyards, Offshore Marine, Pond Services, Arborists, etc. | Used to raise windows, open and close sunroofs, construction industries, etc. | Used in construction, shipping, and manufacturing industries for lifting and moving heavy machinery, equipment, and materials. |

| Inspection | Synthetic web slings are easy to inspect compared to wire rope slings. | Compared to other slings in comparison, they are difficult to inspect due to how they are constructed. | These are very easy to inspect compared to the other slings with synthetic web slings taking the 2nd place.. |

| Protection | Also, compared to the other slings, synthetic web slings can keep delicate loads as well as surfaces well protected. | Misuse of wire ropes can lead to accidents eventually which means it cannot protect loads for long when overused. | Can damage or crush sensitive or finish parts with ease. This makes it the least among these slings. |

Depending on your unique specifications, GUOFENG offers many accessories according to your specifications. Tell us your specific needs for our team to recommend the best wire rope sling, chain sling, or synthetic web sling.

More Resources:

Wire Rope Sling – Source: GOUFENG

Wire Rope – Source: WIKIPEDIA

Wire Rope vs. Chain – Source: GOUFENG