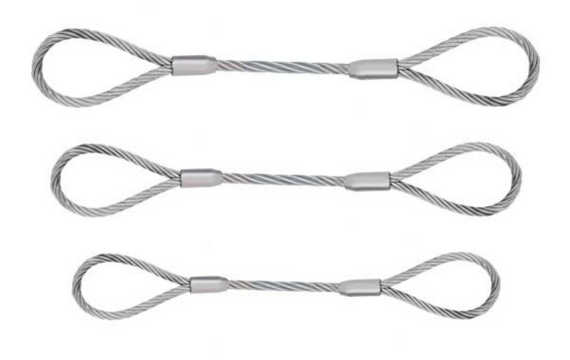

Wire rope sling is a type of lifting equipment made of metal wire rope. It is widely used in various industries, such as construction, shipping, mining, and manufacturing, for hoisting and rigging applications. Wire rope sling is an essential part of the lifting system, and it plays a crucial role in ensuring safety and efficiency during lifting operations.

Definition of Wire Rope Sling

A wire rope sling is a load-bearing assembly of metal wire rope, fittings, and hardware, specially designed for lifting and rigging purposes. It typically consists of one or more strands of wire rope that are fastened together at the ends with different types of fittings, such as hooks, thimbles, sleeves, and sockets. It is used to lift and move heavy loads by attaching it to a crane or other lifting equipment.

How to Choose a Wire Rope Sling?

Choosing the right wire rope sling is crucial for the safety and efficiency of lifting operations. Here are some factors to consider when selecting a wire rope sling:

1. Load Capacity – The load capacity of the wire rope sling should be equal to or greater than the weight of the load being lifted. It is essential to consider both the vertical and horizontal load capacity.

2. Working Length – The working length of the wire rope sling is the distance between the attachment points. It is essential to select a wire rope sling with a working length that is suitable for the lifting height and configuration.

3. Type of Load – The type of load being lifted, its size, and shape will determine the type of wire rope sling needed. It is crucial to consider whether the load is heavy, fragile, or has sharp edges.

4. Environment – The working environment plays a crucial role in selecting a wire rope sling. Factors like temperature, chemicals, and moisture can affect the performance and life of the wire rope sling, so it is essential to choose one that is suitable for the specific working conditions.

5. Material – Wire rope slings are made of different materials, including carbon steel, stainless steel, and galvanized steel. The type of material used will depend on the intended use and working environment.

Wire Rope Sling – Heavy Duty Lifting Solution

Wire rope slings are a popular choice for heavy duty lifting applications, providing strength, flexibility, and durability. They are made from premium quality steel wire, utilizing a high strength construction for maximum load capacity. The unique woven design ensures equal distribution of weight, reducing stress on individual wires. With various end termination options available, our they can easily be attached to hoists, cranes, or other lifting equipment. Whether you need to lift large, heavy objects or handle rough terrain, they are the ideal solution for your lifting needs.

1.What is the weight limit for wire rope slings?

The weight limit for it varies depending on factors such as diameter, length, and configuration of the sling. It is important to consult the manufacturer’s specifications and adhere to proper safety guidelines when determining weight limits.

2.Can wire rope slings be used for lifting liquids?

No, they are not suitable for lifting liquids. Specialized equipment and expertise is required for lifting liquids safely.

3.Can wire rope slings be used on sharp edges or corners?

Yes, it can be used on sharp edges or corners, but it is important to use protective corner protectors to prevent damage to the sling. The manufacturer’s specifications should also be consulted to ensure the appropriate type and size of sling is used.

4.What are the advantages of using wire rope slings?

It have a high strength-to-weight ratio, excellent flexibility and resistance to abrasion and crushing. They are also highly resistant to chemicals, UV rays, and extreme temperatures, making them suitable for use in various industries.

5.Are there any safety precautions for using wire rope slings in confined spaces?

Yes, additional safety precautions must be taken when using it in confined spaces. This includes proper ventilation, anchoring, and following safety guidelines for confined spaces.

6.How should wire rope slings be inspected for damage or wear?

During a visual inspection, areas of potential damage or wear should be examined closely. This may include abrasions, breaks or cracks in the wire, and distortion or deformation of the sling. The entire length of the sling and its connections should be inspected.

7.How should wire rope slings be cleaned?

To clean wire rope slings, it is recommended to use a mild soap and water solution, followed by thorough rinsing and drying. Avoid using harsh chemicals or solvents as they may damage the sling.

8.Are there any precautions to take when using wire rope slings?

Yes, precautions should be taken when using it, such as avoiding sudden jerks or shock loading, and not exceeding the recommended weight limit. Proper lifting techniques and following manufacturer guidelines are also important.